Paradigm Insights™

Engineering Reliability

Simplifying Sealing

Explore articles, guides, and resources from Paradigm Seals™—covering installation & maintenance, the Paradigm difference, pump compatibility & applications, seal sizing & selection, and strategies for long-term value & reliability. Our mission is to give operators the knowledge they need to make confident decisions and reduce downtime.

Explore by Category or scroll down to browse.

The True Cost of Mechanical Seal Downtime — and How to Prevent It

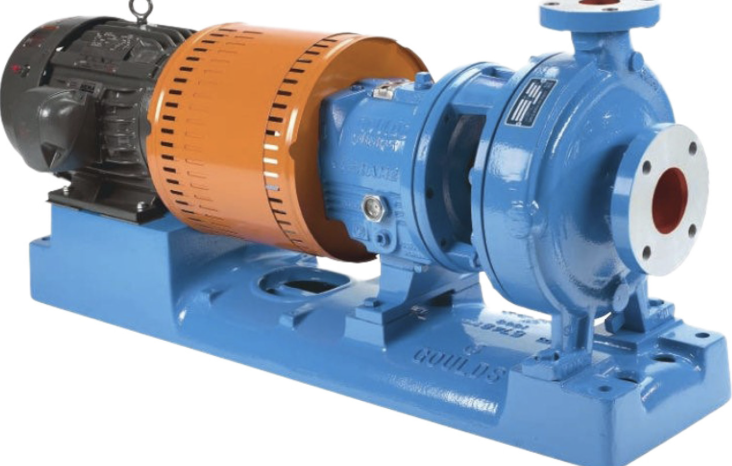

Unplanned downtime caused by mechanical seal failure is one of the most expensive issues in pump operation. Beyond the direct cost of replacing a seal, downtime can result in lost production, safety risks, and environmental compliance violations. Understanding the full cost impact of seal downtime highlights the importance of proactive maintenance and reliable seal selection.

Troubleshooting Mechanical Seal Failures: Common Causes and Corrective Actions

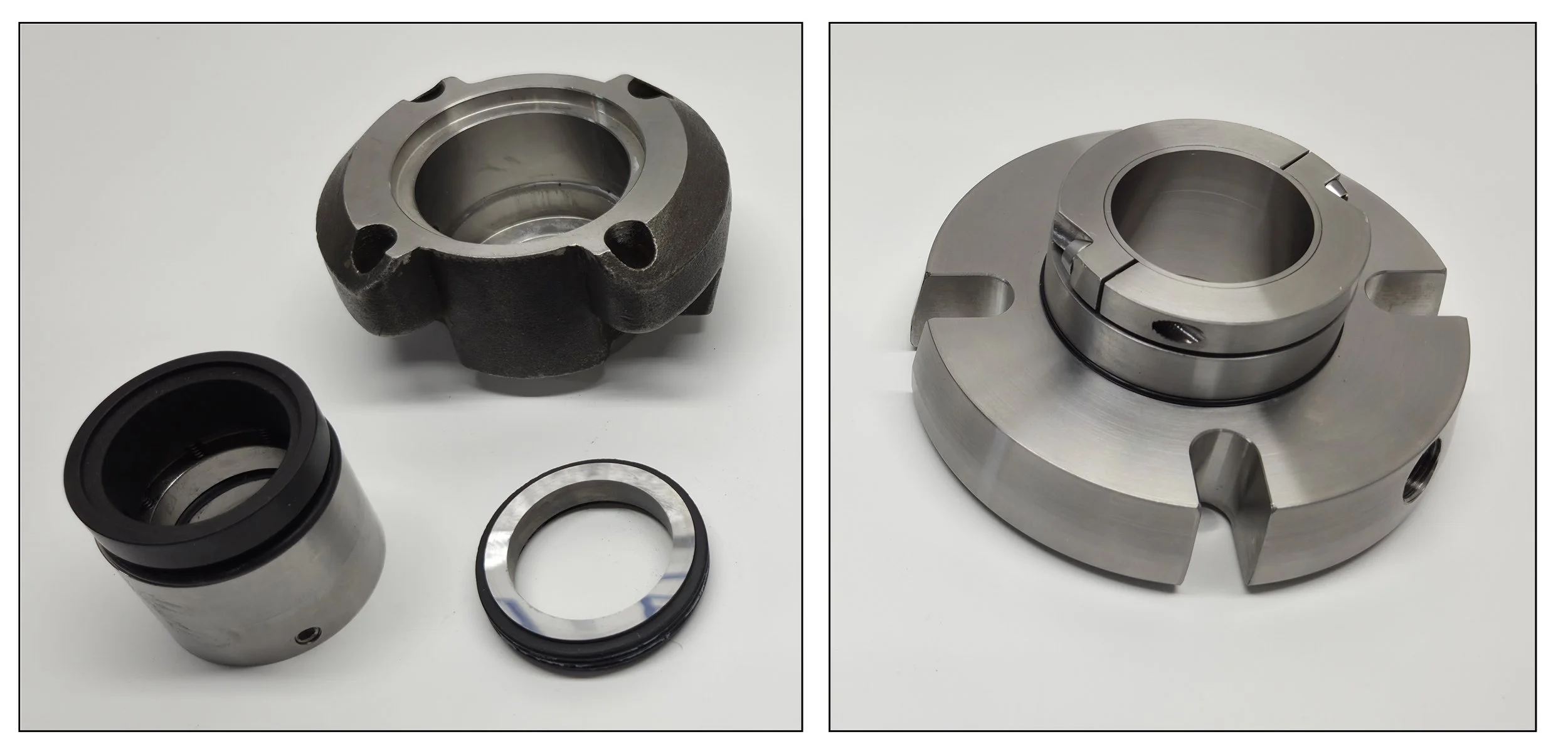

Mechanical seal failures account for a significant percentage of pump downtime across industries. While seals are engineered for reliability, improper installation, inadequate operating conditions, or material incompatibility can shorten service life. Troubleshooting failures begins with understanding the most common causes and implementing corrective actions to prevent recurrence.

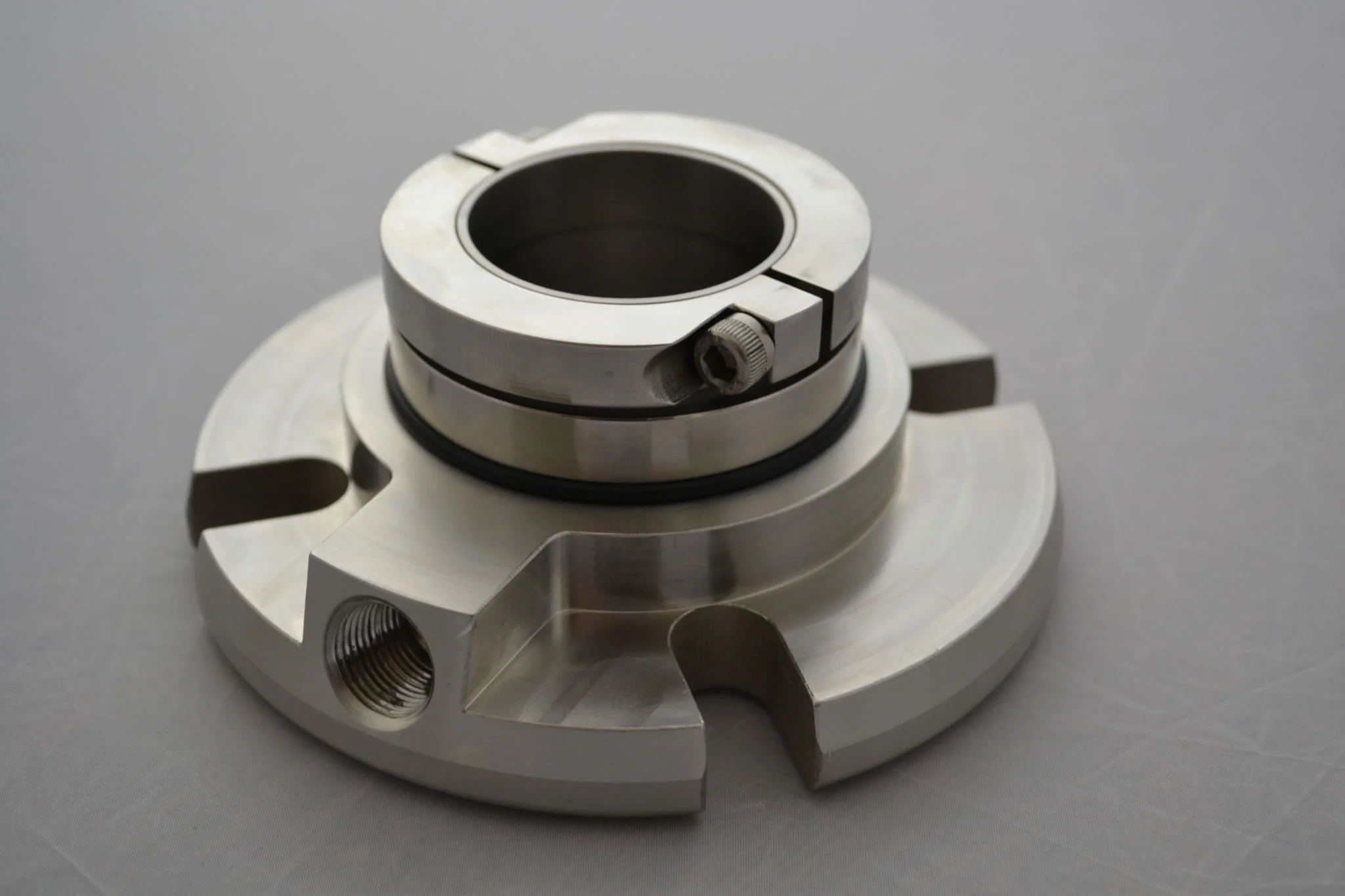

Mechanical Seal Maintenance Checklist for Long-Term Reliability

Mechanical seals are critical components in pump systems, designed to prevent leakage, maintain pressure, and protect equipment. Their reliability directly affects production efficiency, operating costs, and plant safety. Proactive maintenance is the most effective way to extend seal life, reduce unplanned downtime, and ensure consistent performance. This checklist outlines best practices for routine inspections, scheduled maintenance, and long-term reliability.