How to Measure a Mechanical Seal Size (Step-by-Step Guide)

Why Measuring Your Seal Matters

Selecting the right mechanical seal starts with accurate measurements. A mismatch—even by a fraction of an inch—can cause leaks, early failure, or costly downtime. This quick guide walks you through the three critical measurements: Outside Diameter (OD), Inside Diameter (ID), and Width.

Tools You’ll Need

Vernier or digital calipers (for precision)

Clean rag or brush (remove debris before measuring)

Notepad or Seal Sizing Guide (to record your numbers)

Step 1: Measure the Seal’s Outside Diameter (OD)

The OD is the outermost edge of the seal face or gland.

Place your calipers on the outside edge of the stationary ring.

Record the diameter to the nearest 0.001 inch (or 0.1 mm).

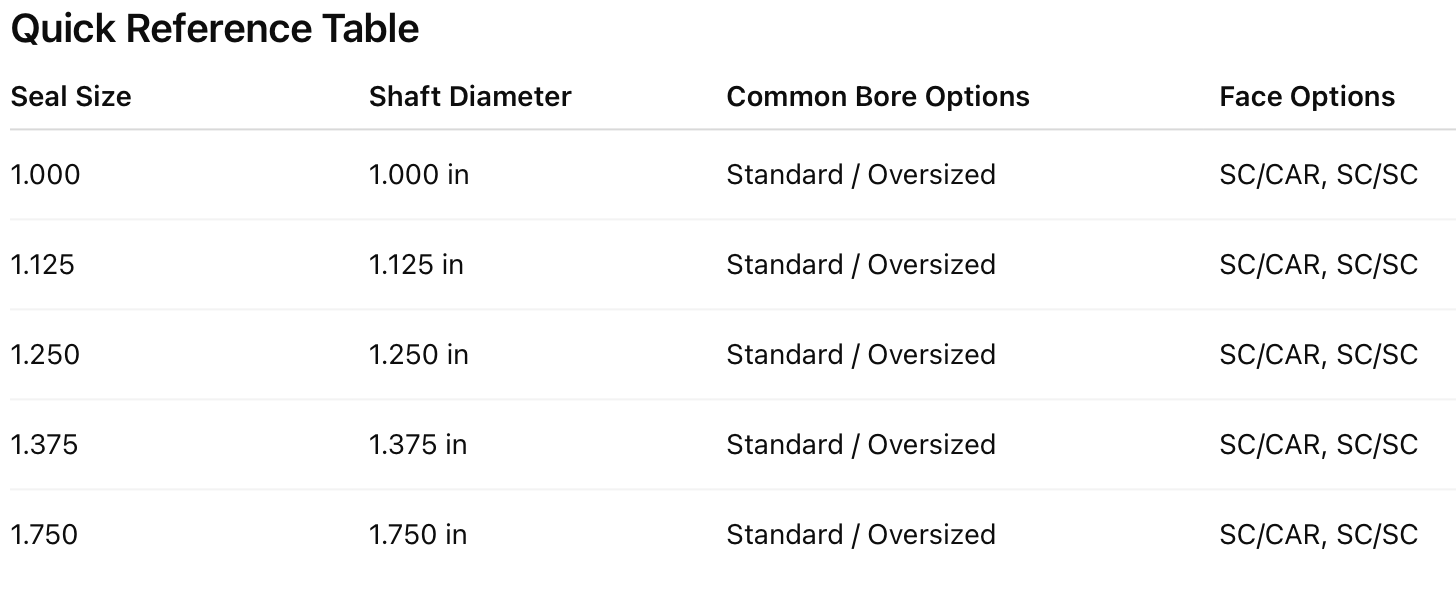

💡 Tip: For Paradigm Seals®, common OD sizes correspond to seal sizes (e.g., 1.000, 1.125, 1.250, 1.375, 1.750).

Step 2: Measure the Seal’s Inside Diameter (ID)

The ID is the inner opening where the pump shaft passes through.

Insert your calipers into the inner bore.

Record the measurement.

This confirms the shaft size, which must match your seal.

Step 3: Measure the Seal Width

Width ensures proper fit inside the stuffing box.

Place your calipers across the seal from front face to back edge.

Record the total thickness.

Step 4: Identify Bore Type (Standard vs. Oversized)

After measuring, confirm whether your pump requires a standard bore or oversized bore:

Standard Bore: Most pumps; matches typical shaft OD.

Oversized Bore: Larger bore to accommodate specific pump models or repairs.

📌 Paradigm’s A1 and A2 Seals are available in both standard and oversized bore options.

Step 5: Cross-Reference with Your Pump Manufacturer

Once you have your three key numbers (OD, ID, Width), check against:

Your pump’s manufacturer (e.g., Goulds, Aurora, Durco, Worthington)

The pump model (e.g., Goulds 3196, Aurora 380)

Paradigm’s Seal Selector Form (available on our Find Your Seal page)

Common Mistakes to Avoid

❌ Measuring with a ruler instead of calipers

❌ Forgetting to clean residue or buildup before measuring

❌ Mixing up OD and ID

❌ Ignoring the bore type (Standard vs. Oversized)

Final Step: Order with Confidence

Once you’ve confirmed your measurements, you can confidently order the correct Paradigm Seal. If you’re unsure, use our Find Your Seal Form or contact our support team with your measurements and pump details.

Ready to order? Browse our [A1 and A2 Cartridge Seals] in the Paradigm Store.

Need extra guidance? Download the Seal Sizing & Manufacturer Guide (PDF).