Repair vs. Replace: Making the Right Decision for Mechanical Seals

When a mechanical seal fails, maintenance teams often face a critical decision: repair the existing seal or replace it with a new one. Both options have advantages, and the right choice depends on the value of the seal, the criticality of the equipment, and the cost of downtime. This article provides a framework for making an informed decision.

When Repairing a Seal Makes Sense

Seal repair, sometimes called seal reconditioning, involves restoring components such as faces, O-rings, and springs to functional condition.

Best suited for:

High-value, custom-engineered seals

Seals used in critical pumps where immediate replacement parts are unavailable

Facilities with access to in-house or third-party repair services

Advantages:

Lower cost compared to purchasing a new custom seal

Reduced waste through reuse of hardware

Can restore seals to “like new” performance when executed properly

When Replacement Is the Better Option

Standard cartridge seals are often more cost-effective to replace than repair.

Best suited for:

Standard cartridge seals with typical materials such as 316SS and carbon graphite

Applications where downtime costs exceed the savings from repair

Seals with severe wear, corrosion, or broken hardware

Advantages:

Immediate availability of replacement seals

Lower labor requirements than reconditioning

Guaranteed performance with new components

Factors to Consider in the Decision

Seal Cost vs. Downtime Cost: For low-cost cartridge seals, replacement is often faster and less expensive overall.

Seal Condition: Cracked faces, damage due to failed bearings or corroded hardware typically justify replacement.

Application Criticality: Mission-critical pumps in hazardous or regulated industries may warrant repair or expedited replacement.

Lead Time: Repair lead time vs. the availability of replacement seals is often the deciding factor when downtime costs are high.

Paradigm’s Approach

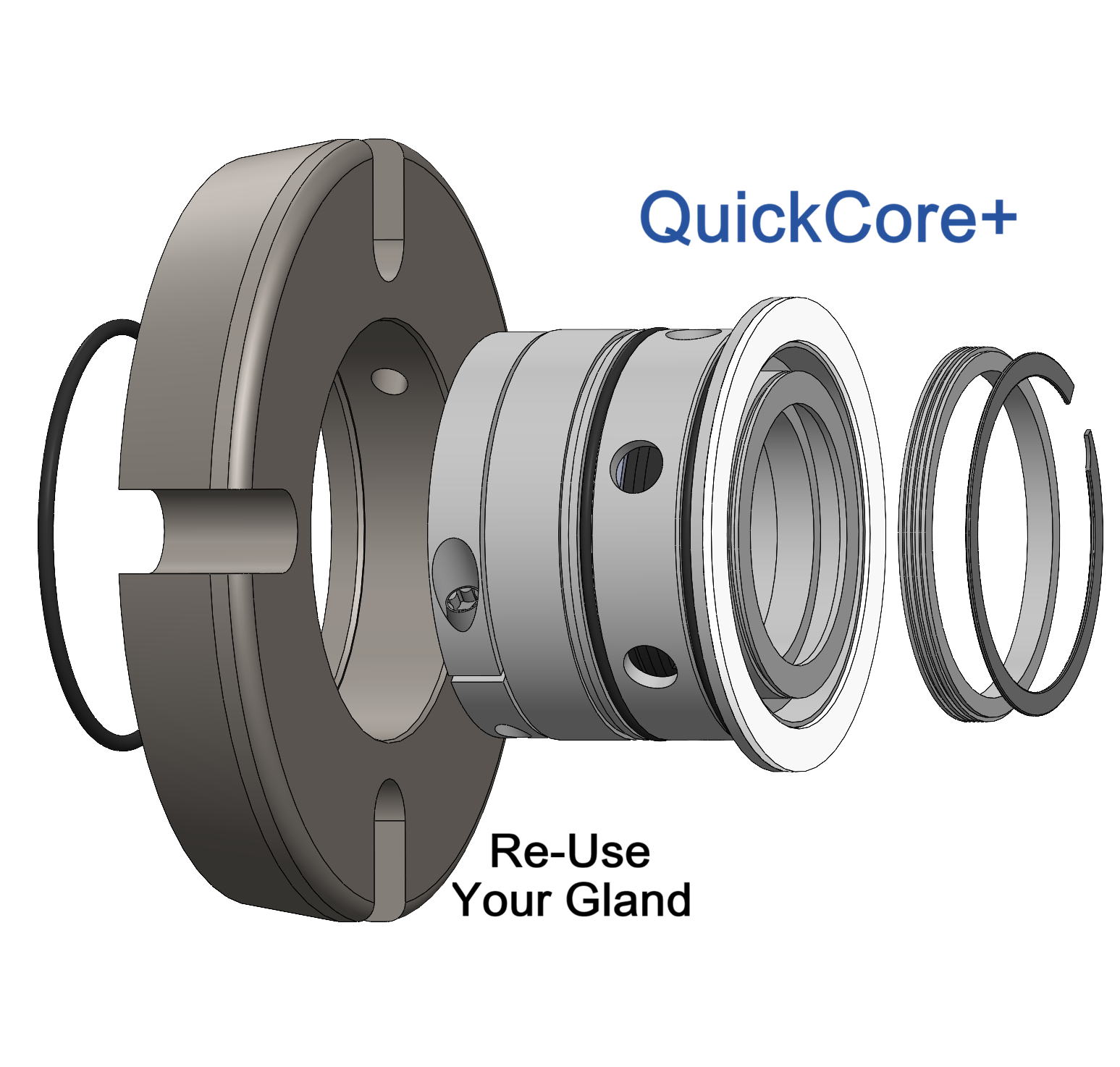

Paradigm Seals™ are designed for on site repair using Paradigm Seals QuickCore+, ensuring customers can quickly restore pump reliability without lengthy downtime. With QuickCore+ availability fitting both standard and oversized bore seals, multiple face combinations, and compatibility across leading pump manufacturers, Paradigm seals simplify the decision to replace rather than repair.

Paradigm Seals QuickCore+™ gives you the peace of mind of a new, factory-tested seal.

Key Takeaway

For most standard cartridge seals, replacement is faster, lower risk, and more cost-effective than repair. QuickCore+™ makes the decision easy by minimizing downtime while delivering consistent, reliable performance.