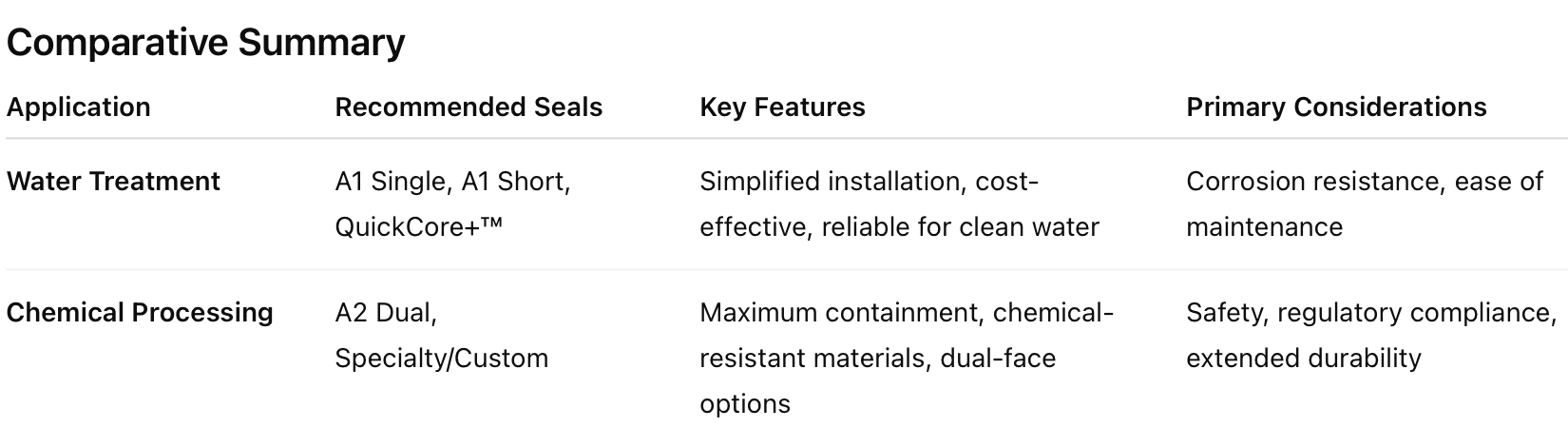

Choosing the Right Seal for Water Treatment vs. Chemical Processing Applications

Mechanical seals must be matched not only to pump design but also to the application environment. Two of the most common — yet very different — applications are water treatment and chemical processing. Each presents unique challenges that affect seal selection, materials, and maintenance strategies. This article compares both environments and outlines best practices for choosing the correct Paradigm seal.

Mechanical Seals in Water Treatment Applications

Operating Environment:

Typically clean or lightly contaminated water

Moderate pressure and temperature ranges

Continuous operation requirements

Recommended Seals:

A1 Single Cartridge Seal for general water pumping

A1 Short Cartridge Seal for compact pump installations

QuickCore+™ repair system for rapid replacement during planned maintenance

Key Considerations:

Long service life with minimal operator intervention

Cost-effective, straightforward installation

Protection against corrosion from treated water or trace chemicals

Mechanical Seals in Chemical Processing Applications

Operating Environment:

Corrosive, abrasive, or hazardous fluids

Higher temperatures and pressures

Strict safety and environmental containment requirements

Recommended Seals:

A2 Dual Cartridge Seal with SC/SC/SC/SC faces for maximum chemical resistance

Specialty/Custom Seals for unique chemical compatibility requirements

Key Considerations:

Leakage control to protect operators and meet regulatory compliance

Material selection (Silicon Carbide vs. Silicon Carbide for aggressive fluids)

Oversized bore options for pumps modified to handle corrosive service

Paradigm’s Advantage

With a full portfolio of cartridge seals — from the A1 Single to the A2 Dual and QuickCore+™ systems — Paradigm Seals™ provides tailored solutions for both water treatment and chemical processing industries. Our compatibility guarantee ensures that seals are engineered to meet the unique demands of each application.

Key Takeaway

Water treatment and chemical processing present very different sealing challenges. Selecting the right mechanical seal means evaluating not just pump type but also process fluid, operating conditions, and safety requirements. Paradigm Seals® offers proven solutions to maximize performance in both environments.