Paradigm Insights™

Engineering Reliability

Simplifying Sealing

Explore articles, guides, and resources from Paradigm Seals™—covering installation & maintenance, the Paradigm difference, pump compatibility & applications, seal sizing & selection, and strategies for long-term value & reliability. Our mission is to give operators the knowledge they need to make confident decisions and reduce downtime.

Explore by Category or scroll down to browse.

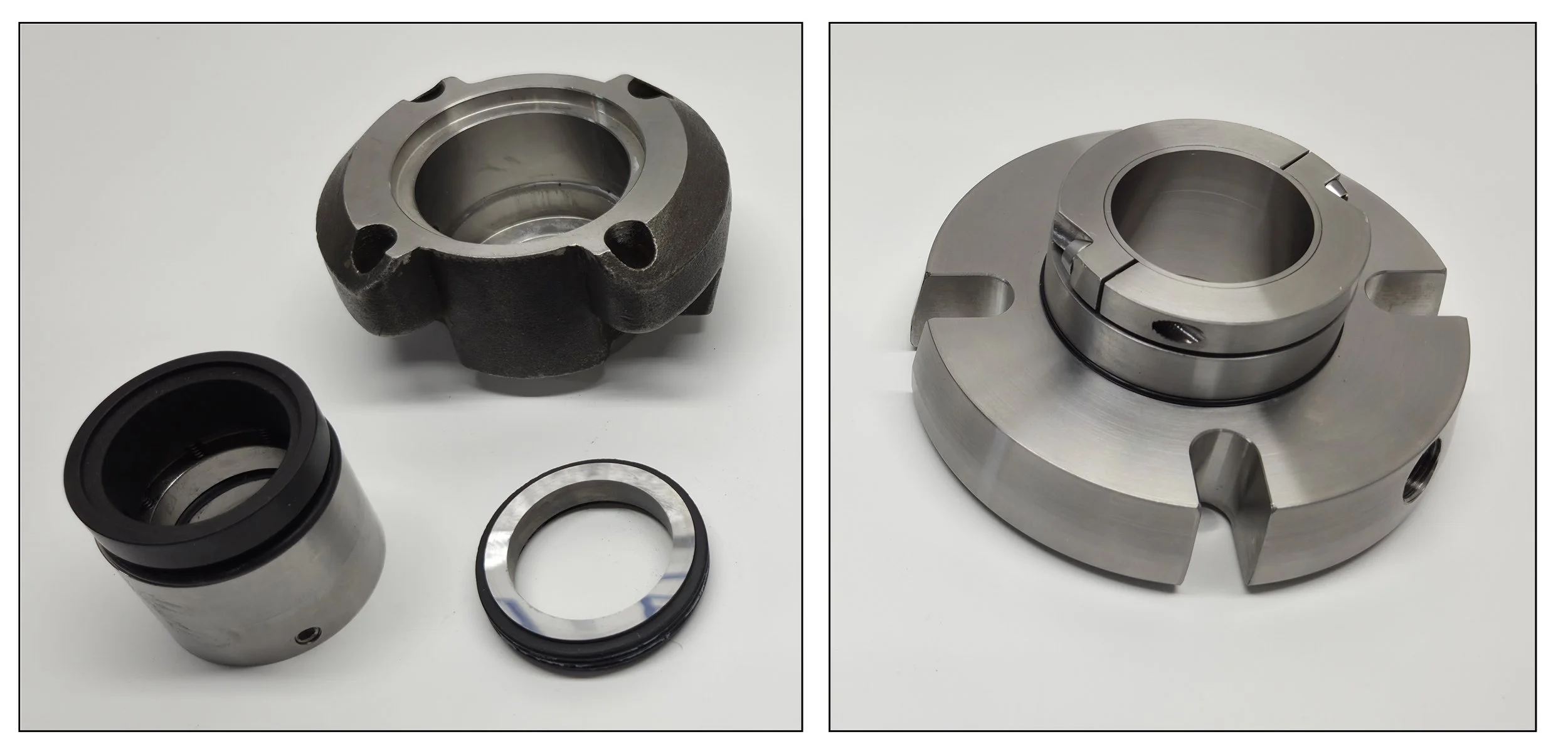

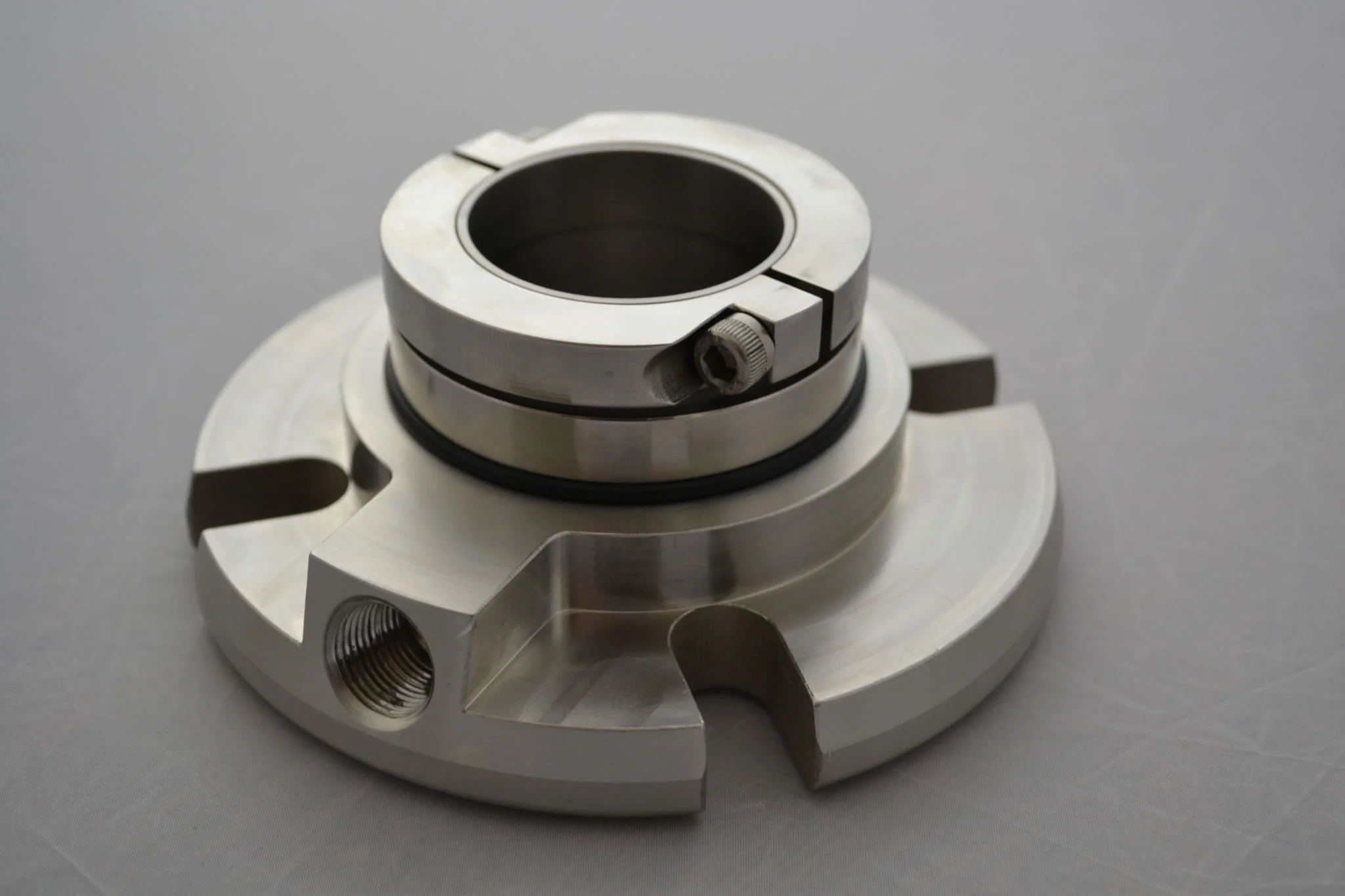

The Anatomy of a Cartridge Mechanical Seal

Cartridge mechanical seals are often viewed as a standardized solution, but the details of their design play a major role in performance, reliability, and maintenance. From how a seal is centered and installed to how its faces are balanced and supported, small design choices can have a significant impact on seal life and ease of service. Understanding the anatomy of a cartridge seal helps maintenance professionals and engineers make better decisions, reduce downtime, and improve overall pump reliability.

Carbon vs. Silicon Carbide: Choosing the Right Mechanical Seal Faces

When it comes to mechanical seal performance, few decisions matter more than selecting the right seal face combination. The materials you choose directly affect seal reliability, pump uptime, and overall maintenance costs.

How to Install the A1 Single Cartridge Seal | Step-by-Step Guide with Video

Installing a mechanical seal doesn’t need to be complicated. The Paradigm Seals™ A1 Single Cartridge Seal is designed for simplified installation, improved reliability, and reduced downtime. By following the proper steps, operators can ensure correct alignment, secure fit, and long-lasting performance.

To make installation easy, we’ve prepared this step-by-step video and guide.

Understanding Oversized Bore Mechanical Seals

When selecting a mechanical seal, confirming the correct bore size is just as important as choosing the right seal type and face combination. For many pumps, a standard bore will suffice. However, certain pump models and applications require an oversized bore. Misidentifying this detail can lead to incorrect orders, failed installations, and costly downtime.

This article explains what an oversized bore is, when it’s required, and how Paradigm Seals™ makes the selection process simple.

The Paradigm i-Seal™ Story: Redefining Mechanical Seal Innovation

The mechanical seal industry has long relied on legacy designs with incremental improvements. Paradigm Seals® took a different approach — one that prioritizes simplicity, reliability, and long-term value for operators. The result is the i-Seal® family of cartridge seals, engineered to eliminate common sealing frustrations while delivering consistent performance across industries.

5 Ways Paradigm Seals™ Simplify Installation and Reduce Maintenance Costs

Mechanical seals are often associated with complex installation, frequent maintenance, and costly downtime. Paradigm Seals® were engineered to eliminate these challenges. By combining robust materials with simplified cartridge design, Paradigm helps facilities save both time and money while maintaining reliable pump operation.

The True Cost of Mechanical Seal Downtime — and How to Prevent It

Unplanned downtime caused by mechanical seal failure is one of the most expensive issues in pump operation. Beyond the direct cost of replacing a seal, downtime can result in lost production, safety risks, and environmental compliance violations. Understanding the full cost impact of seal downtime highlights the importance of proactive maintenance and reliable seal selection.

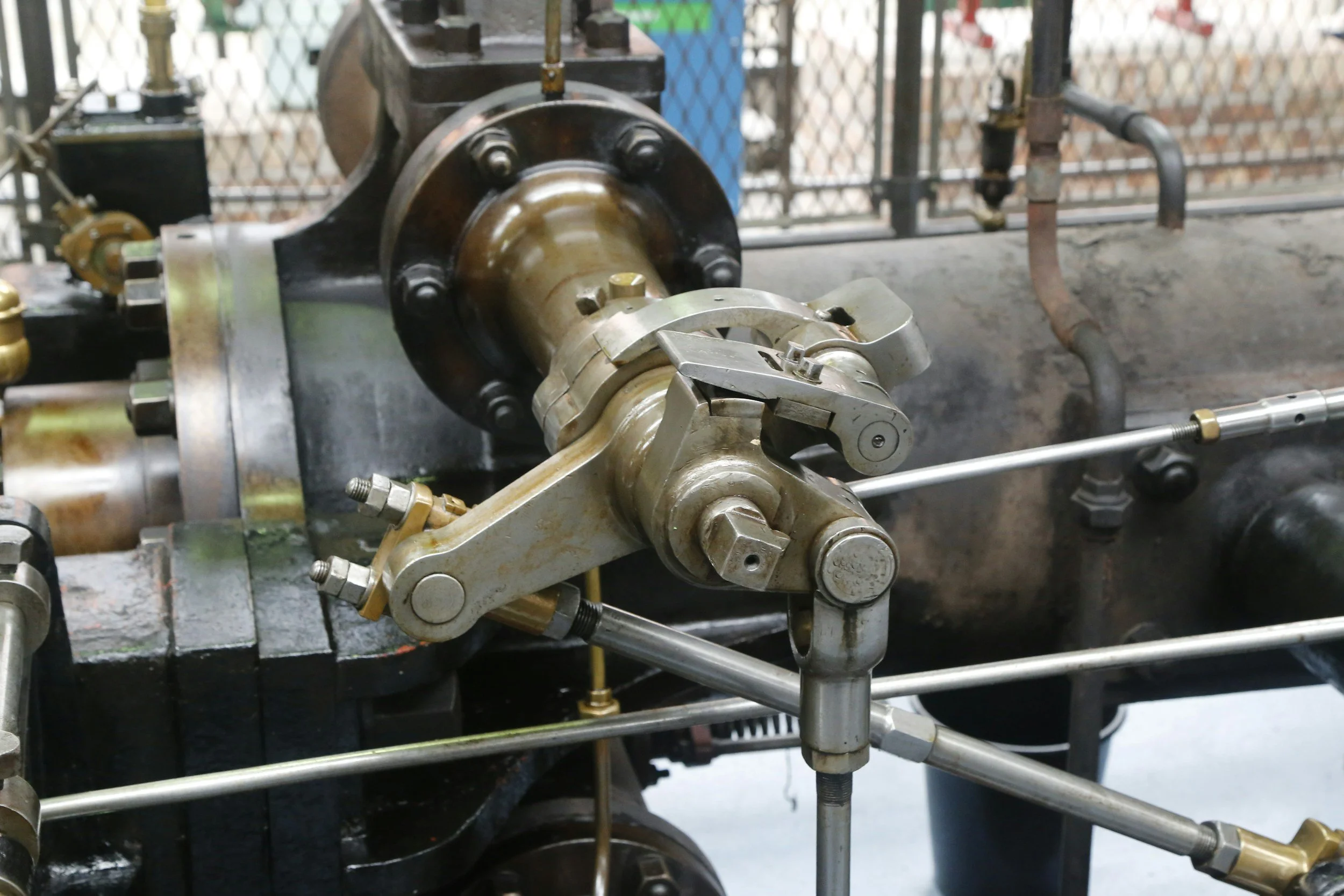

Why Cartridge Seals Save You Time and Money vs. Packing

Pump packing has been used for decades as a sealing method, but modern cartridge mechanical seals offer significant advantages in efficiency, reliability, and cost. For facilities focused on reducing downtime and total cost of ownership, replacing packing with cartridge seals is often the most effective upgrade.

Choosing the Right Seal for Water Treatment vs. Chemical Processing Applications

Mechanical seals must be matched not only to pump design but also to the application environment. Two of the most common — yet very different — applications are water treatment and chemical processing. Each presents unique challenges that affect seal selection, materials, and maintenance strategies. This article compares both environments and outlines best practices for choosing the correct Paradigm seal.

Seal Solutions for Aurora, Durco, and Worthington Pumps

Aurora, Durco, and Worthington pumps are widely used across municipal, industrial, and process applications. From water distribution to chemical handling, these pumps demand seals that deliver consistent performance under varying conditions. Paradigm Seals® provides cartridge seal solutions engineered for compatibility with all three pump families, ensuring reliable operation and simplified maintenance.

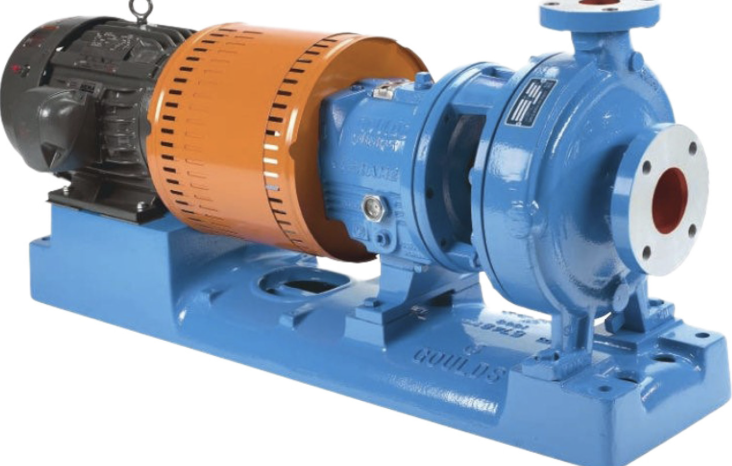

The Best Mechanical Seals for Goulds 3196 Pumps

The Goulds 3196 is one of the most widely used process pumps in the world, trusted across industries from chemical processing to water treatment. Selecting the correct mechanical seal is essential to ensure reliable operation, prevent leakage, and minimize downtime. Paradigm Seals® offers cartridge seals engineered specifically for compatibility with the Goulds 3196, simplifying installation and extending service life.

Repair vs. Replace: Making the Right Decision for Mechanical Seals

When a mechanical seal fails, maintenance teams often face a critical decision: repair the existing seal or replace it with a new one. Both options have advantages, and the right choice depends on the value of the seal, the criticality of the equipment, and the cost of downtime. This article provides a framework for making an informed decision.

Troubleshooting Mechanical Seal Failures: Common Causes and Corrective Actions

Mechanical seal failures account for a significant percentage of pump downtime across industries. While seals are engineered for reliability, improper installation, inadequate operating conditions, or material incompatibility can shorten service life. Troubleshooting failures begins with understanding the most common causes and implementing corrective actions to prevent recurrence.

Mechanical Seal Maintenance Checklist for Long-Term Reliability

Mechanical seals are critical components in pump systems, designed to prevent leakage, maintain pressure, and protect equipment. Their reliability directly affects production efficiency, operating costs, and plant safety. Proactive maintenance is the most effective way to extend seal life, reduce unplanned downtime, and ensure consistent performance. This checklist outlines best practices for routine inspections, scheduled maintenance, and long-term reliability.

Top 5 Mistakes to Avoid When Installing Mechanical Seals

Mechanical seals are precision components — and even small mistakes during installation can lead to premature failure. Whether you’re installing a single cartridge seal or a dual cartridge seal, avoiding these common pitfalls will save time, money, and downtime.

When to Replace a Mechanical Seal: Signs of Wear & Failure

Mechanical seals are the heart of pump reliability. But like any wear part, they don’t last forever. Waiting too long to replace a failing seal can lead to unexpected downtime, equipment damage, or costly leaks. In this article, we’ll cover the top signs it’s time to replace your mechanical seal and how to extend its lifespan.

Single vs. Dual Cartridge Seals: Which One Do You Need?

One of the most common questions pump operators face is whether to install a single cartridge seal or upgrade to a dual cartridge seal. Both options are engineered for reliability, but each serves a different purpose depending on your operating conditions. This guide will help you decide which is right for your pump.

Standard vs. Oversized Bore Seals: What’s the Difference?

When it comes to replacing or upgrading a mechanical seal, understanding bore size is one of the most important steps in selecting the right product. At Paradigm Seals®, customers often ask: What’s the difference between a standard bore and an oversized bore seal? This guide breaks it down so you can confidently choose the correct option for your pump.

How to Measure a Mechanical Seal Size (Step-by-Step Guide)

Selecting the right mechanical seal starts with accurate measurements. A mismatch—even by a fraction of an inch—can cause leaks, early failure, or costly downtime. This quick guide walks you through the three critical measurements: Outside Diameter (OD), Inside Diameter (ID), and Width.