Why Cartridge Seals Save You Time and Money vs. Packing

Why This Matters

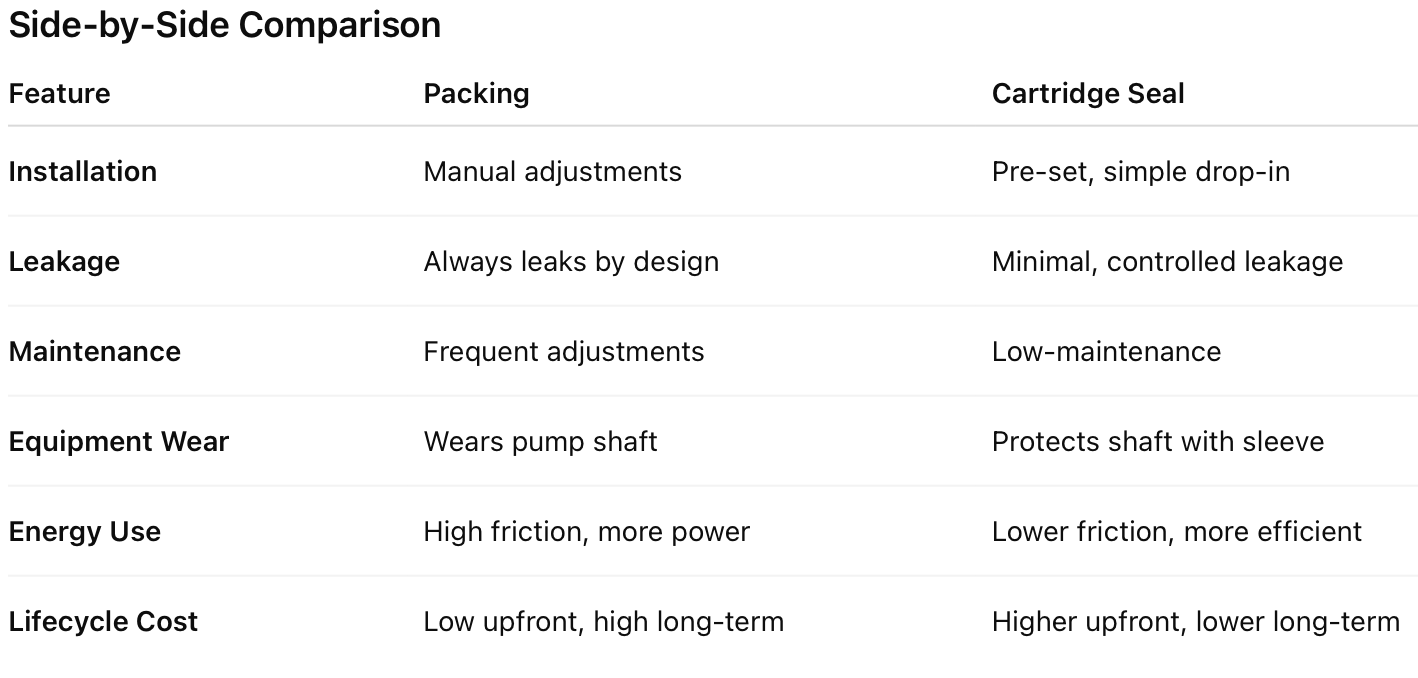

Mechanical seals and packing both serve the same purpose: keeping fluid contained inside a pump. But the differences in reliability, maintenance, and cost are critical for operators to understand.

What is Packing?

Packing uses braided rings of material compressed around the pump shaft.

It relies on friction to limit leakage.

Some leakage is expected and necessary to keep the packing lubricated.

Over time, packing wears the shaft, requires frequent adjustment, and wastes energy through drag.

Packing is inexpensive upfront, but the long-term costs of downtime, maintenance, and shaft repair are high.

What is a Cartridge Seal?

A cartridge seal is a self-contained, pre-assembled unit that houses all sealing elements — faces, sleeve, gland, and O-rings.

Factory-set alignment eliminates the need for adjustments.

Two seal faces (often silicon carbide vs. carbon, or silicon carbide vs. silicon carbide) create a precise barrier with minimal leakage.

Installation is simplified — it’s a “drop-in” solution rather than a custom setup.

Cartridge seals cost more initially, but they deliver lower lifetime costs due to reliability, efficiency, and reduced maintenance.

Industry Shift

The industry has steadily moved from packing to cartridge seals because:

Reliability reduces unplanned downtime.

Energy efficiency lowers operating costs.

Equipment lasts longer with less wear.

Operators spend less time adjusting and repairing seals.

Key Takeaway

Packing still exists in low-cost applications, but cartridge seals are the modern standard for pump reliability. As you move through this course, keep in mind: cartridge seals aren’t just an upgrade — they’re a shift in how maintenance teams ensure long-term performance.