Paradigm Insights™

Engineering Reliability

Simplifying Sealing

Explore articles, guides, and resources from Paradigm Seals™—covering installation & maintenance, the Paradigm difference, pump compatibility & applications, seal sizing & selection, and strategies for long-term value & reliability. Our mission is to give operators the knowledge they need to make confident decisions and reduce downtime.

Explore by Category or scroll down to browse.

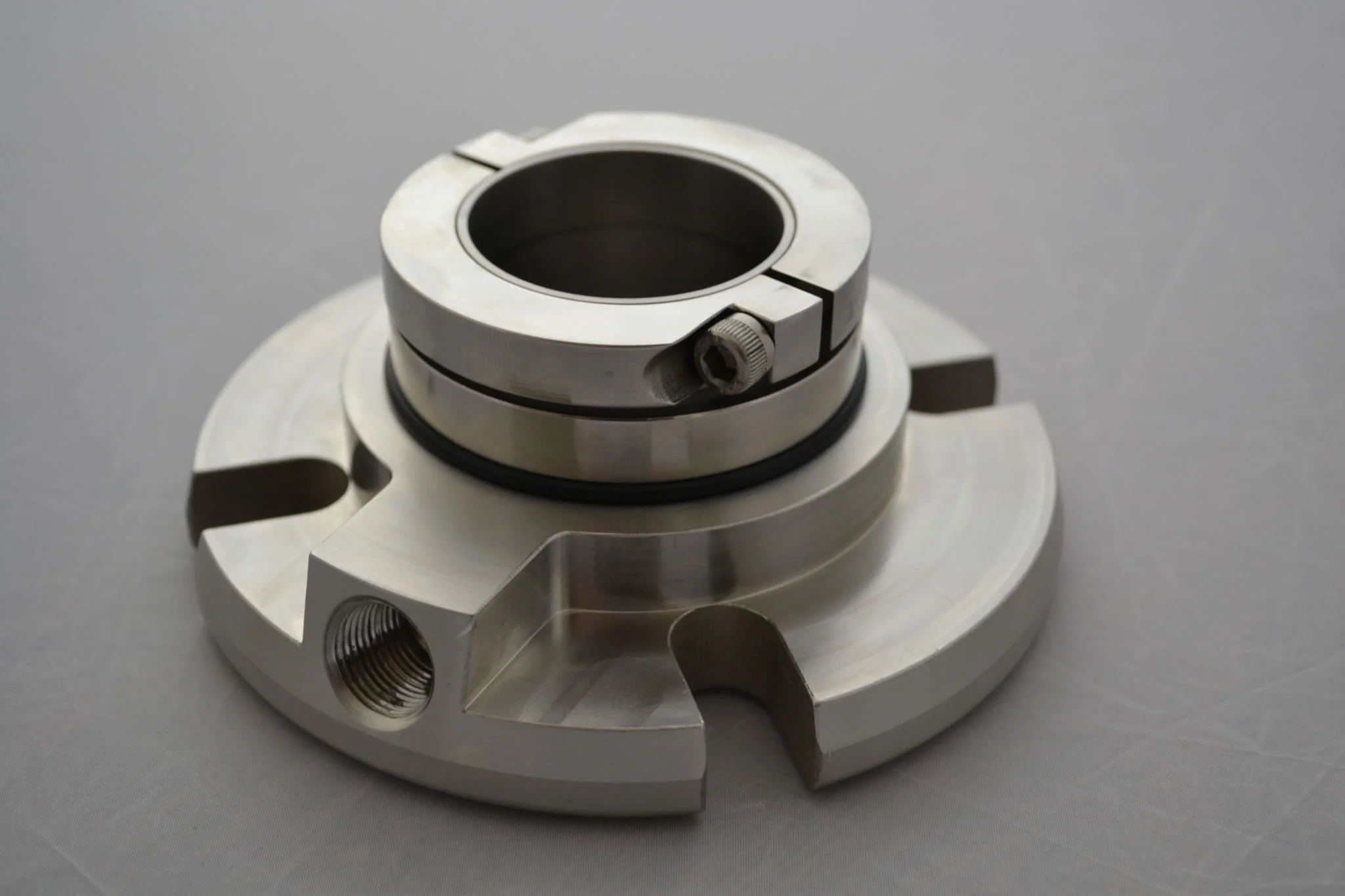

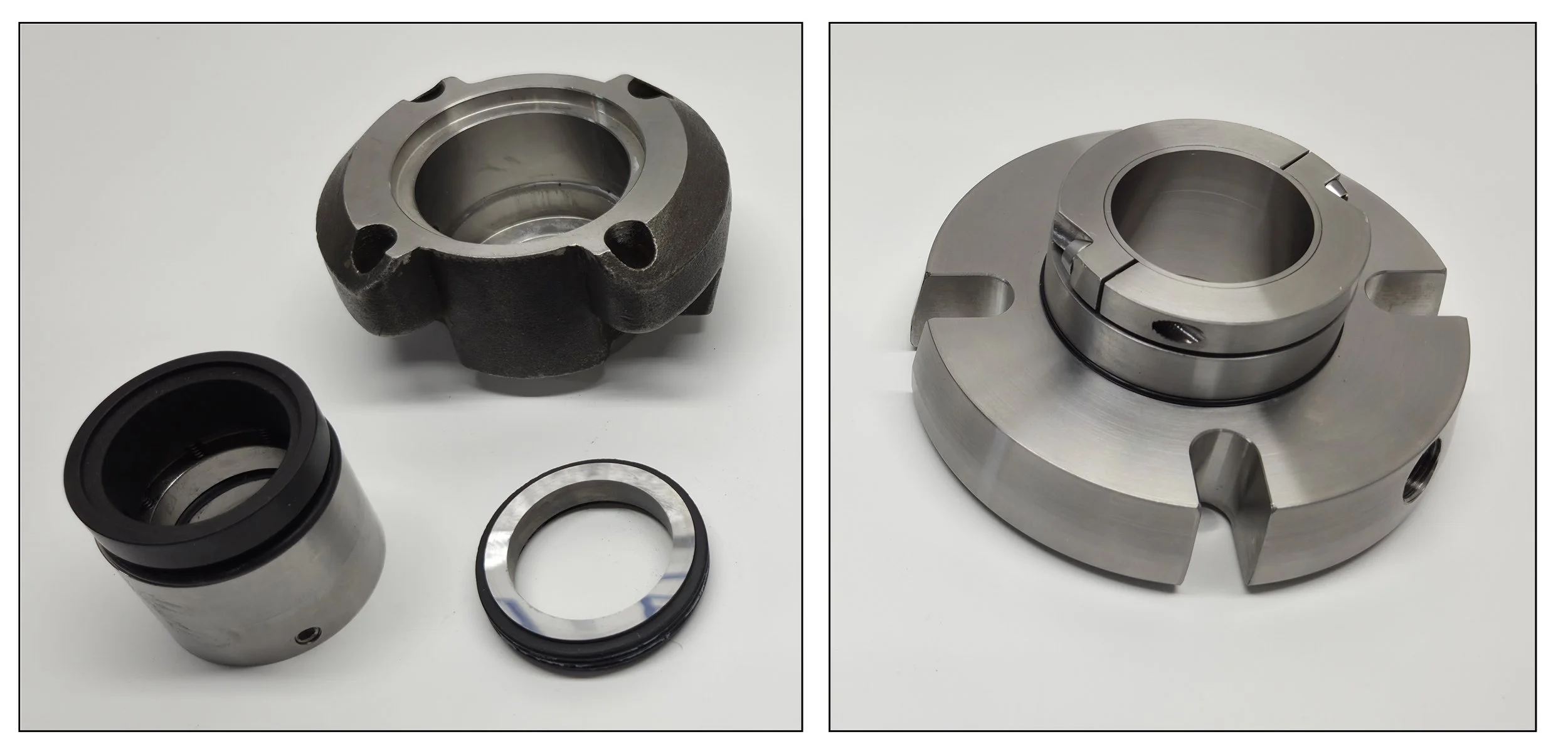

How to Install the A1 Single Cartridge Seal | Step-by-Step Guide with Video

Installing a mechanical seal doesn’t need to be complicated. The Paradigm Seals™ A1 Single Cartridge Seal is designed for simplified installation, improved reliability, and reduced downtime. By following the proper steps, operators can ensure correct alignment, secure fit, and long-lasting performance.

To make installation easy, we’ve prepared this step-by-step video and guide.

Repair vs. Replace: Making the Right Decision for Mechanical Seals

When a mechanical seal fails, maintenance teams often face a critical decision: repair the existing seal or replace it with a new one. Both options have advantages, and the right choice depends on the value of the seal, the criticality of the equipment, and the cost of downtime. This article provides a framework for making an informed decision.

Troubleshooting Mechanical Seal Failures: Common Causes and Corrective Actions

Mechanical seal failures account for a significant percentage of pump downtime across industries. While seals are engineered for reliability, improper installation, inadequate operating conditions, or material incompatibility can shorten service life. Troubleshooting failures begins with understanding the most common causes and implementing corrective actions to prevent recurrence.

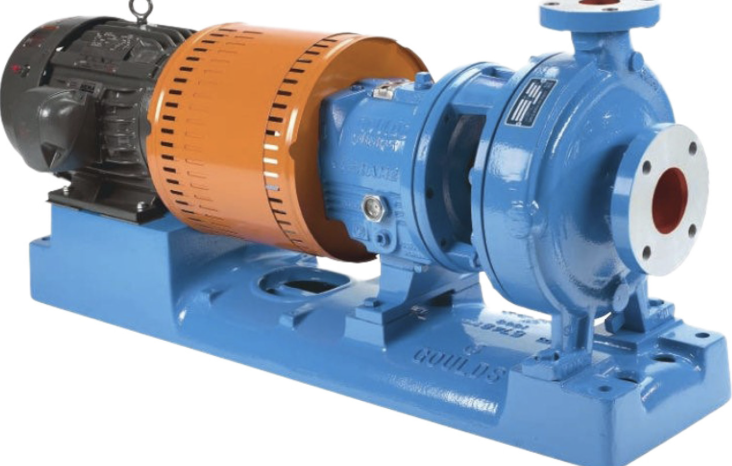

Mechanical Seal Maintenance Checklist for Long-Term Reliability

Mechanical seals are critical components in pump systems, designed to prevent leakage, maintain pressure, and protect equipment. Their reliability directly affects production efficiency, operating costs, and plant safety. Proactive maintenance is the most effective way to extend seal life, reduce unplanned downtime, and ensure consistent performance. This checklist outlines best practices for routine inspections, scheduled maintenance, and long-term reliability.

Top 5 Mistakes to Avoid When Installing Mechanical Seals

Mechanical seals are precision components — and even small mistakes during installation can lead to premature failure. Whether you’re installing a single cartridge seal or a dual cartridge seal, avoiding these common pitfalls will save time, money, and downtime.

When to Replace a Mechanical Seal: Signs of Wear & Failure

Mechanical seals are the heart of pump reliability. But like any wear part, they don’t last forever. Waiting too long to replace a failing seal can lead to unexpected downtime, equipment damage, or costly leaks. In this article, we’ll cover the top signs it’s time to replace your mechanical seal and how to extend its lifespan.