Reliable Mechanical Seals. Simplified Installation.

Proven Quality.

No Set Screws. No Clips. No problems.

Paradigm Seals™ designs cartridge seals that are first in simplifying installation and removal — protecting pump sleeves and shafts, cutting downtime, and delivering long-lasting performance across every industry.

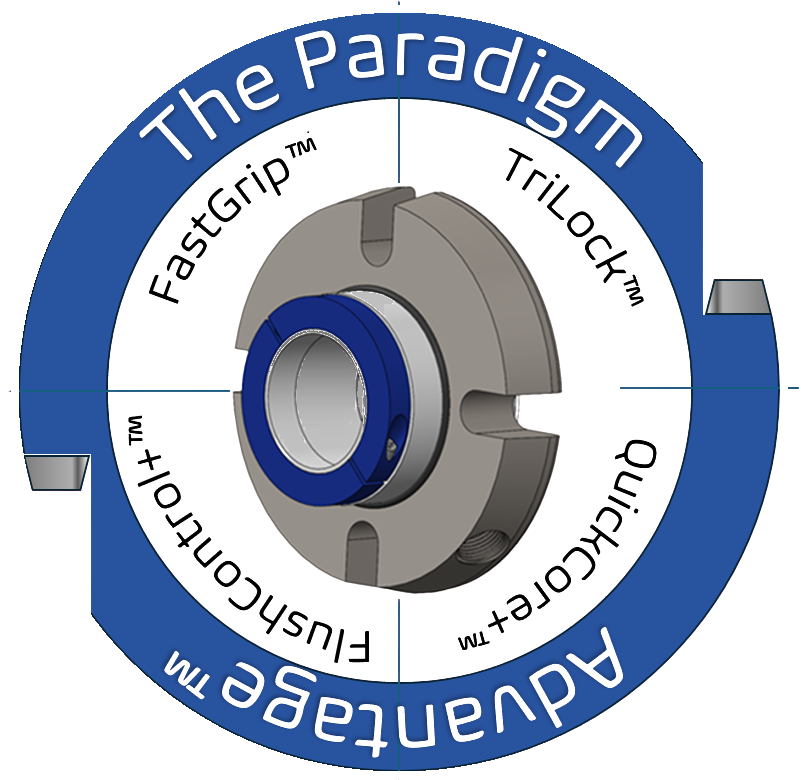

The Paradigm Advantage ™

FastGrip™

The FastGrip™ Clamp eliminates traditional set screws, preventing shaft and sleeve damage while simplifying installation and removal.

It provides secure, even clamping to ensure reliable torque transmission without distortion or scoring. To ensure proper installation, Paradigm includes a T-handle torque wrench and the correct Torx® drive bit, allowing the FastGrip™ clamp to be tightened accurately every time.

Integrated into the seal design, FastGrip™ delivers faster, more reliable installation.

TriLock Bushing™

The TriLock™ Bushing eliminates the need for traditional centering clips and their removal, dramatically simplifying installation.

It automatically aligns the seal on all three axes, maintaining proper spring position for consistent seal face loading. The bushing locks the seal securely in place, helping prevent uneven wear and premature seal failure.

Because the TriLock™ Bushing is integrated into the seal design, it improves reliability without adding steps or complexity — making consistent, repeatable installations easier to achieve.

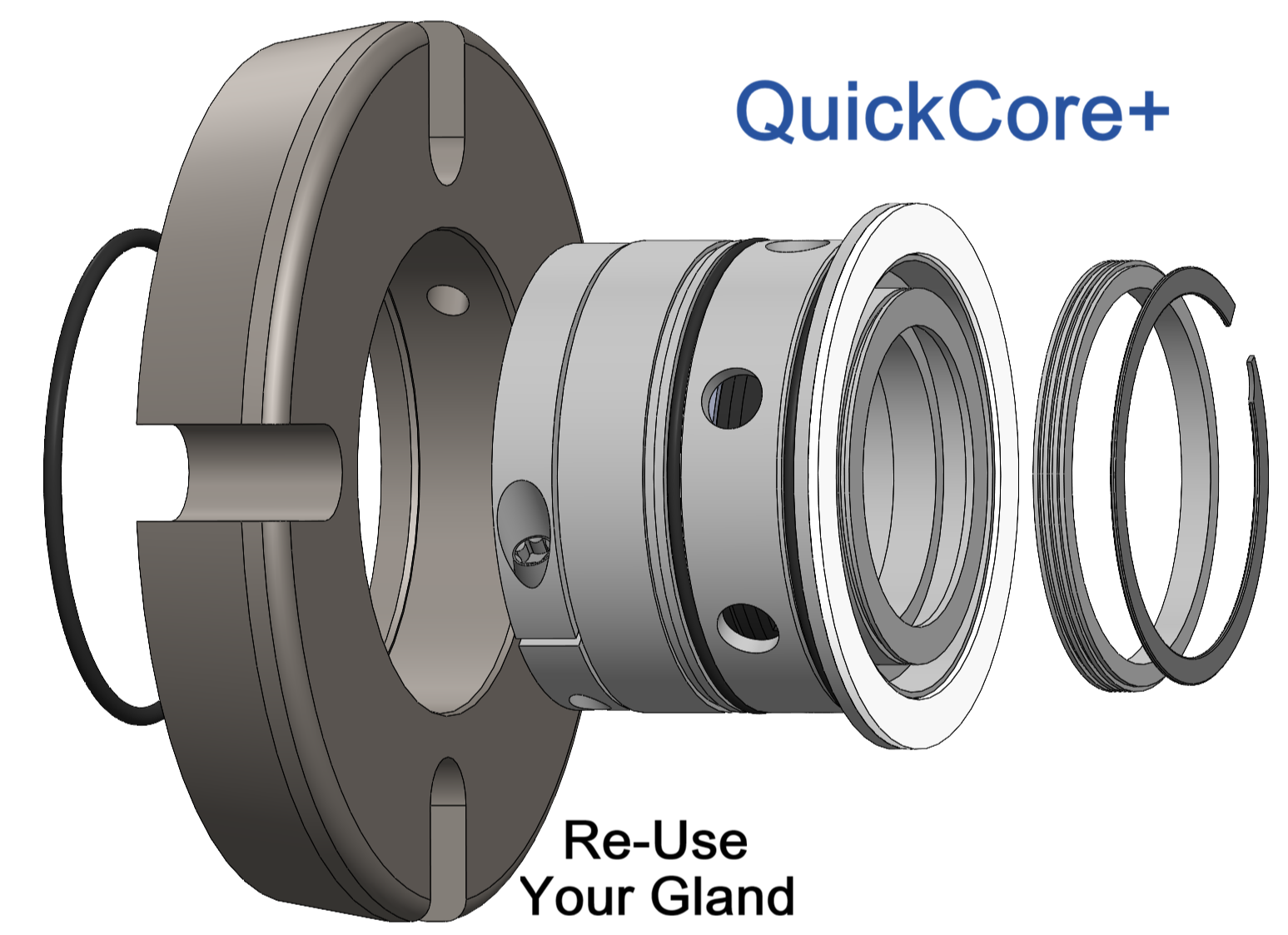

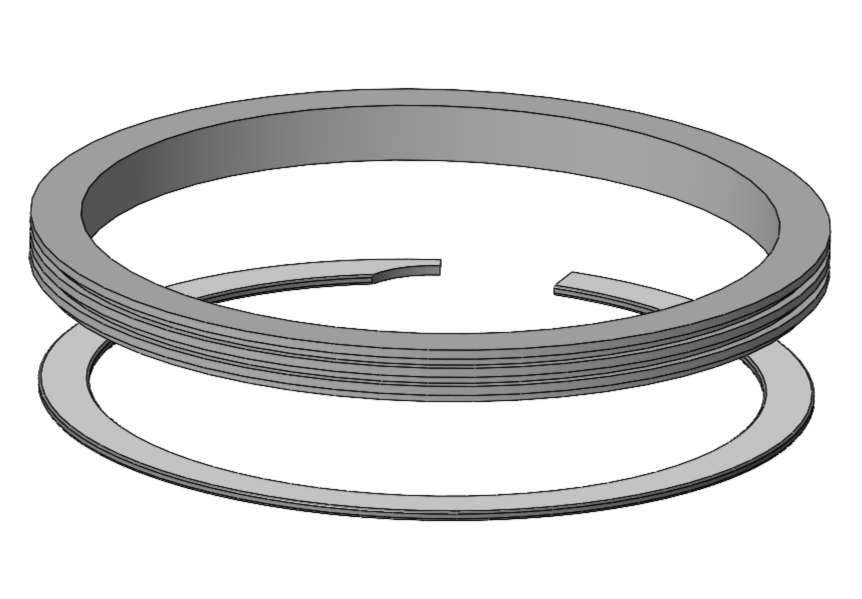

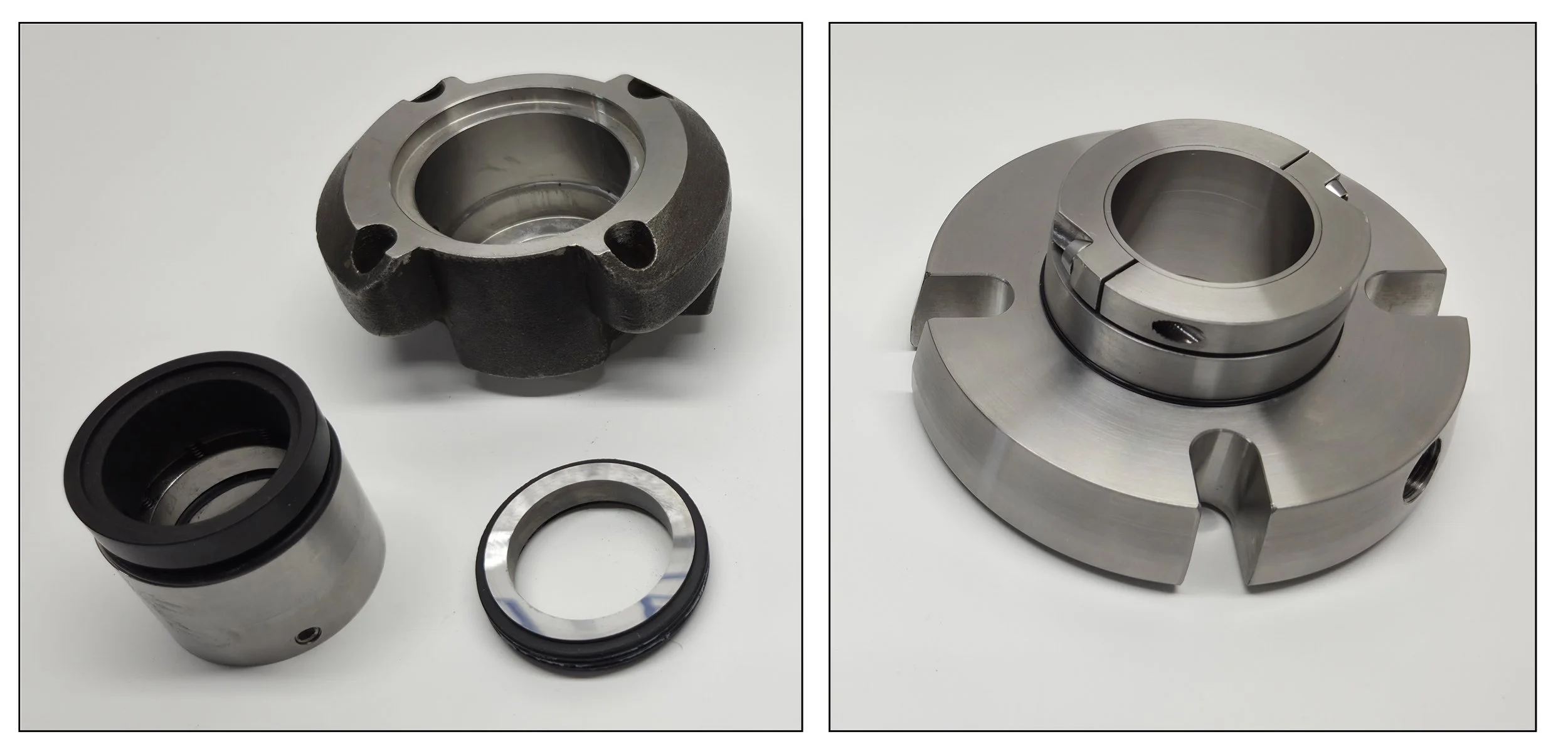

QuickCore+™

QuickCore™ Technology allows you to replace only the core sealing element — not the entire seal — delivering a new, factory-tested seal every time at the same cost as repairing a competitor’s cartridge seal, without the added logistics or downtime of sending your seal out for repair.

By eliminating the traditional repair process, QuickCore™ removes the need to clean and decontaminate used seals, gather cartridges for the storeroom, create purchase orders, package and ship seals out, or wait for a quotation — only to find the seal is beyond repair.

FlushControl+™

The FlushControl™ Bushing is an optional feature included with the seal. When used, it is installed directly into the seal as part of the assembly and is designed to manage flush flow to the seal faces — improving lubrication, cooling, and overall seal performance.

When installed, the FlushControl™ Bushing helps reduce excess flush flow, minimizes dilution of the process fluid, conserves water, and improves reliability. It is especially beneficial in applications with flashing or near-flashing fluids, where maintaining proper lubrication and cooling is critical.

A Seal for Every Application.

iSeal A1 Single Cartridge Seal

Our most popular seal — fast installs, reduced costs, maximum reliability.

View A1 SealiSeal A2 Dual Cartridge Seal

Compact design with built-in pumping ring for stable, high-performance applications.

View A2 SealiSeal A3 Short Cartridge Seal

Same innovative design, made for tight spaces and cost-conscious operations.

View A3 Short Seal

See All Products

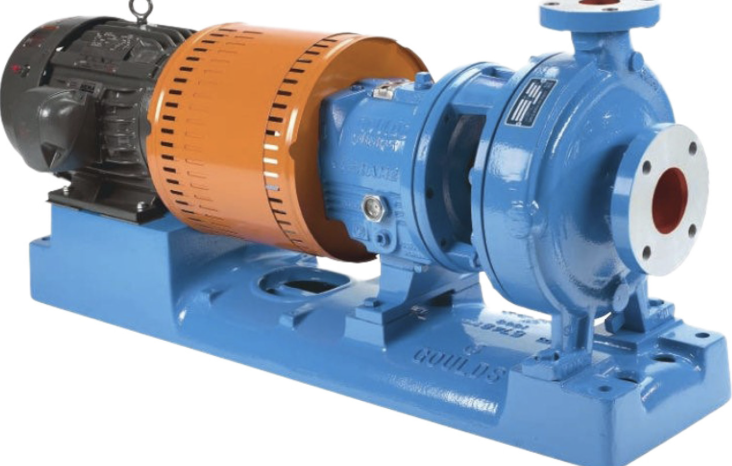

Engineered to Fit the Pumps You Run Every Day

-

ANSI Pumps

Precision Fit for Standard ANSI Process Pumps

Built for the rigorous demands of chemical and industrial process service — easy installs, reliable sealing. -

End-Suction Pumps

Simplified Sealing for Common Plant Workhorses

Fast, dependable installation keeps your single-stage end-suction pumps online longer. -

Vertical Pumps

Reliable Seals for Vertical Turbine & Sump Applications

Engineered to handle challenging alignment and shaft conditions while reducing maintenance. -

Split-Case Pumps

Long-Life Sealing for High-Flow, Double-Suction Pumps

Designed to minimize downtime and protect shafts in large, high-volume systems.

The Right Seal, Every Time.

Use our easy tools to match seals by pump model, size, or industry application.

Industries served

-

Water & Wastewater

-

Oil & Gas

-

Power Generation

-

Food & Beverage

-

Agribusiness

Resources

insights

Built on trust. Driven by performance.

or

Mechanical seals are critical components in pump systems, designed to prevent leakage, maintain pressure, and protect equipment. Their reliability directly affects production efficiency, operating costs, and plant safety. Proactive maintenance is the most effective way to extend seal life, reduce unplanned downtime, and ensure consistent performance. This checklist outlines best practices for routine inspections, scheduled maintenance, and long-term reliability.